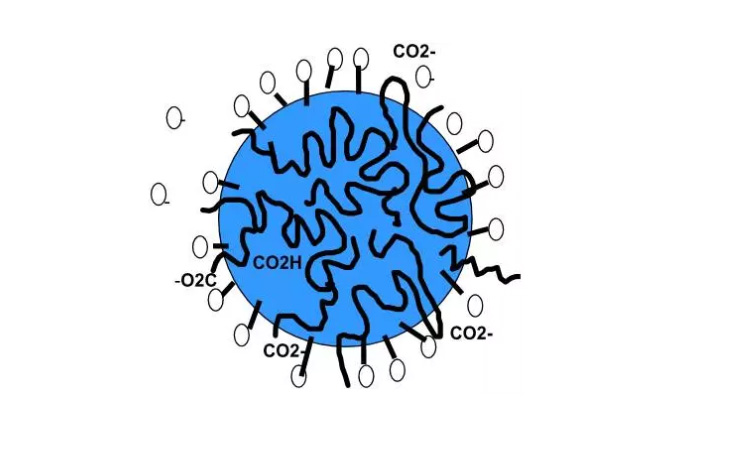

SBR is the most widely used water-based binder, 98% of lithium electrode binder used SBR. SBR is the English abbreviation of styrene butadiene latex, SBR binder solid content is generally 49%~51%, easily soluble in water and polar solvents, with high bonding strength and good mechanical stability and operability, used in the battery industry as a binder, binder effect is good, stable quality. The amount of anode binder usually accounts for 1.5% of the anode material.

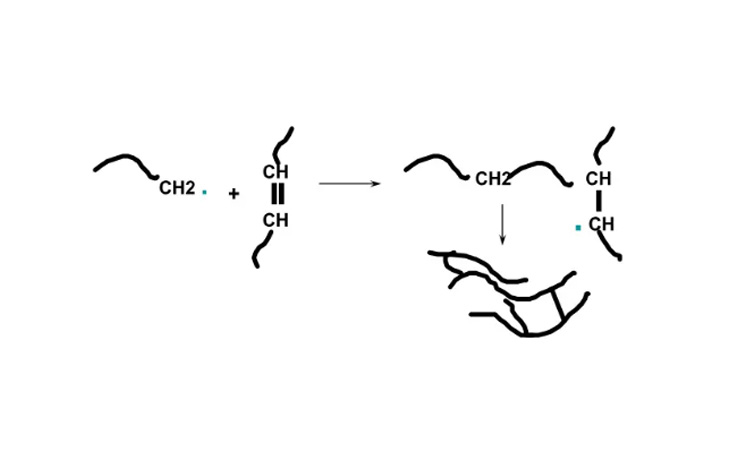

From the perspective of SBR industry chain, the upstream is mainly chemical raw materials, including 1, 3-butadiene, styrene, catalysts and other additives; The middle reaches are SBR emulsion manufacturers; Downstream applications are mainly water-soluble binders for power batteries, consumer batteries and energy storage batteries.

3.1. Shipments of lithium ion batteries

In terms of shipments of lithium ion batteries, according to the Ministry of Industry and Information Technology, shipments of lithium ion batteries in 2021 reached 324GWh, a year-on-year increase of 106%. From January to February 2022, China's lithium ion battery industry maintained a rapid growth trend, with shipments exceeding 82GWh.

3.2. Measurement of SBR binder demand and market size

According to relevant data, 1GWh battery needs 856 tons of graphite, and the amount of negative electrode binder accounts for 3% of the negative electrode material. It can be calculated that in 2021, 324GWh lithium battery needs 8320 tons of SBR binder. If the current average market price is 125,000 yuan/ton, the corresponding market size is 1.04 billion yuan.

3.3. Current situation of import and export

Styrene butadiene rubber latex customs code 40021110. In terms of import and export, our imports are greater than exports. According to statistics, in 2021, the import volume of styrene butadiene latex will be 91,500 tons, and the import amount will be 915 million US dollars.

From the perspective of average import price, the substantial growth of lithium battery production in 2021 will bring about a rise in the market price of lithium battery accessories. According to statistics, the average import price of styrene butadiene latex in China in 2021 is $2131.1 / ton.

From import regions, Europe and Asia are the main import regions in our country, with imports accounting for 46.3% and 41.3%, respectively. In terms of the distribution of import countries, Germany, Japan and South Korea are the main importers, accounting for 37.1%, 23.8% and 13.7% respectively.

4.1. Industry concentration

From the perspective of global market competition, SBR binder occupies 98% of the negative binder market. In the SBR binder market, foreign products have dominated the market for many years, and in recent years, domestic products have gradually replaced imported products. At present, the market share of Jingrui in negative electrode binder has reached 44%, sharing the domestic negative electrode binder market with Rayon, A&L and JSR.

4.2. Introduction of key enterprises

Rayon Group in Japan is the leading enterprise of negative electrode water-based binder, its technology and products are in the forefront of the industry. Japan's A&L Corporation and JSR Corporation are also excellent performers in the industry. In recent years, Jingrui Co., Ltd. has made rapid development in negative electrode binder and gradually realized the import substitution of negative electrode binder.

As a water-based binder, SBR has the following advantages in terms of performance:

1. The decomposition temperature of water-based binder is higher than 270℃ and it has good thermal stability; 2. In terms of processing stability, compared with conventional emulsion, water-based binder has good freeze-thaw resistance, and will not break milk under high-speed shear, with excellent grinding stability, very suitable for mechanical dispersion with powder; 3. In terms of storage and transportation stability, conventional emulsion will appear demulsification curing failure after below freezing point, and water-based binder will not demulsification even if the temperature is below freezing point. When the temperature is restored to above freezing point, that is, liquidity can still be continued to use; 4. In terms of processing, it breaks through the limitation of low efficiency of solvent-based binder, greatly improves the production efficiency of coating, and its compaction density can be comparable to the traditional oil system PVDF. Job-related technology is gradually mature, especially the gradual development of positive water-based binders, water-based binders will eventually replace oily binders.

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat