Model:AS-BSR2300

Product Origin:China

Product Description: Mainly used for material evaluation, formulation evaluation, and sedimentation performance evaluation of positive and negative electrode slurries and conductive agent slurries for lithium (sodium) batteries.

Product Description

AS-BSR2300 battery slurry resistivity tester through the upper, middle and lower three pairs of electrodes synchronous detection of slurry vertical height resistivity (range 2.5Ω-cm-50mΩ-cm, accuracy ± 0.5%), accurate assessment of lithium / sodium batteries, positive and negative electrode slurry conductivity uniformity and static settlement performance. The device is built-in 0.01μS/cm high-resolution module, supporting 80mL sample volume one-key start test, real-time recording of resistivity, temperature and time change curve, suitable for 5 times the GRR analysis of parallel samples (repeatability and reproducibility verification). With ultrasonic cleaning electrode pen (deionized water for 30 seconds) and dust-free paper drying process to ensure data reliability. The net weight of the machine is 5kg, size 210×300×120mm, compatible with 0-40℃ ambient temperature and humidity, providing an efficient quantitative tool for the optimization of laboratory paste formulations and the evaluation of conductive agent dispersion.

|

Product Name |

Battery Slurry Resistance Tester |

|

Model |

AS-BSR2300 |

|

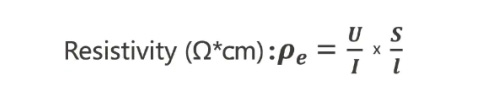

Resistivity measurement range |

2.5Ω*cm-50mΩ*cm |

|

Resistivity measurement resolution |

0.01μS/cm |

|

Resistivity measurement accuracy |

±0.5% |

|

Voltage |

220-240V |

|

Voltage variation tolerance |

±10% |

|

Power |

<80W |

|

Environmental temperature |

0-40℃ |

|

Environmental humidity |

<80%RH |

|

Net wet |

5kg |

|

Dimension |

W210*D300*H120 mm |

Test steps: Putting a certain volume of slurry (~80mL) into the measuring glass, inserting a clean electrode pen, start the software, start to test the changes in the slurry resistivity at the three pairs of electrodes over time and save it in the file.

Test parameters: Resistivity, Temperature, Time

Test program: Three operators, five parallelsamples, and random testing.

Test method: Sonicating the electrode pen withdeionized water for 30 seconds,and drying it with the dust-freepaper. Then five parallel sampleswas tested, and the fifth set of datawas taken for the GRR analysis.

Company Profile

Xiamen AS battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AS Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Certificate

Cooperative Partner

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat