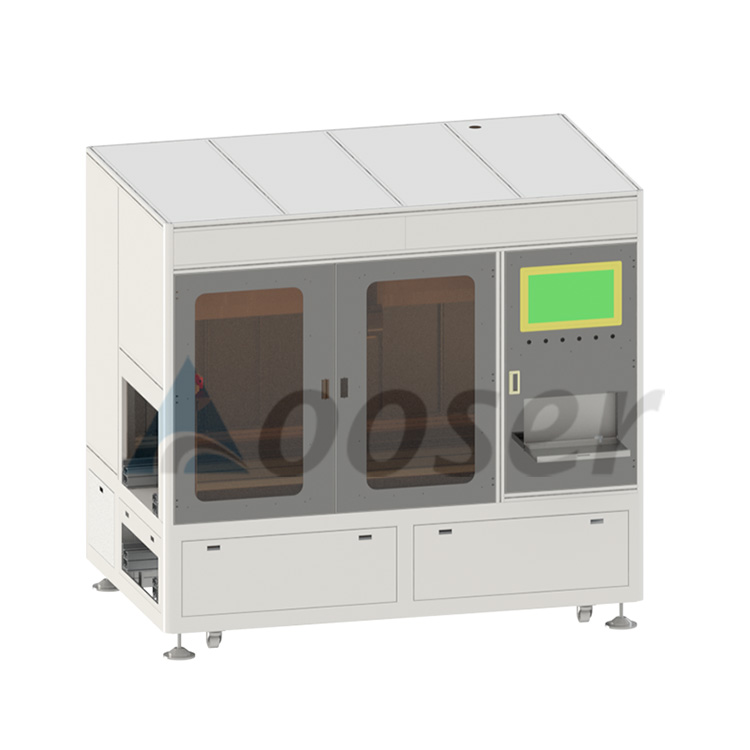

Model:AS-LCW-200/3000

Product Origin:China

Product description: AS-LCW-200/3000 battery lug laser cleaning and welding machine, 200W cleaning + 3000W welding dual-module, CCD vision positioning accuracy of 0.1mm, 8PPM high-efficiency production, yield rate of 99% or more, suitable for power battery lugs full-automatic precision machining, support for trajectory and power segmentation adjustment.

Product Description

AS-LCW-200/3000 battery lug laser cleaning and welding machine integrates 200W cleaning laser and 3000W continuous fiber welding module, through the CCD vision secondary positioning (accuracy ≤ 0.1mm) and servo drive system, to achieve the lug cleaning coverage > 80%, welding height difference ≤ 0.08mm precision processing. The equipment adopts aluminum frame structure (1200×700×300mm motion platform), equipped with dual-temperature and dual-control water cooling system and smoke purification module, supporting 8PPM continuous production rhythm, yield ≥ 99%. The cleaning track and welding power are adjustable in segments, which is suitable for removing oxides on the surface of aluminum/copper lugs and welding the connecting piece of 2mm height difference of the battery cell, meeting the high efficiency and high stability processing requirements of the fully automated production line of power batteries and energy storage battery modules.

Technical specifications

Equipment operating environment conditions

Air and dust: free from salt containing gases, toxic and corrosive gases; There should be no conductive dust.

Magnetic field and vibration: There is no magnetic field that affects the use of the device and no impact or vibration.

Temperature and humidity: 10℃~35℃/humidity: 10~55RH

Power supply: 380/220ACV ± 10% 50/60Hz;

Compressed air: 0.5~0.7Mpa;

Noise: ≤ 80% dB (measured 1 meter away from the wall)

Equipment parameters

Whole line production efficiency

8PPM

Equipment electrical

AC380V/50Hz

Total power consumption of the equipment

22KW

Compressed air

0.5~0.7Mpa

Equipment appearance color

The upper and lower frames are made of aluminum profiles and brown matte finish

Equipment operation utilization rate

≥ 95%

Equipment operation yield rate

≥ 99%

Laser welding electrode cleaning

Function description and configuration list:

1. After the mechanism is lifted and positioned, the CCD addressing system performs secondary positioning of the pole position, and then completes automatic cleaning of the pole.

2. Cleaning position accuracy: ≤ 0.2mm.

3. Cleaning coverage area: greater than 80%.

4. Cleaning trajectory: The trajectory can be adjusted arbitrarily, and the power segmentation can be adjusted arbitrarily.

5. Two electrodes/poles can be cleaned at once while meeting the rhythm.

6. Automatic laser cleaning of equipment.

Main configuration list

|

Section |

Spec |

Qty |

|

|

Laser cleaning |

Movement system |

1200*700*300mm |

1 |

|

Mechanical assembly |

Customized |

1 |

|

|

Control system |

HMI |

1 |

|

|

CCD vision system |

Camera: Hikvision |

1 |

|

|

Servo motor |

400 |

4 |

|

|

Industrial control computer |

Customized |

1 |

|

|

Laser device |

200W |

1 |

|

|

Smoke Purifier |

/ |

1 |

|

Laser Welding

Function description and configuration list:

1. The CCD addressing system performs secondary positioning of the pole position, the pressure head component presses down on the connecting piece, automatically measures the height, and then completes automatic welding.

2. Welding position accuracy: ≤ 0.1mm, with a height difference of about 2mm between the battery cell connection pieces.

3. Welding trajectory: The trajectory can be adjusted arbitrarily, and the power can be segmented and adjusted arbitrarily.

4. Adopting a single pressure head, pressing down one aluminum row at a time.

5. Laser ranging is required during welding, with a resolution of ≤ 0.05mm and a detection repeatability accuracy of ≤ 0.08mm.

Main configuration list

|

Section |

Spec |

Qty |

|

|

Flexible intelligent welding station |

Movement system |

1200*700*300mm |

1 |

|

Mechanical assembly |

Customized |

1 |

|

|

Pressing device |

Customized |

1 |

|

|

Control system |

HMI |

1 |

|

|

Laser system |

Fiber laser |

3000W Continuous |

1 |

|

Galvo Scanning Head |

G320 |

1 |

|

|

|

CCD visual ranging system |

Camera: Hikvision |

1 |

|

Cooling system |

Water cooler |

Dual temperature and dual control |

1 |

|

|

Servo motor |

400 |

4 |

|

|

Industrial control computer |

Customized |

1 |

|

|

Smoke Purifier |

/ |

1 |

Company Profile

Xiamen AS battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AS Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Certificate

Cooperative Partner

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat