Model:AS-MSK-H2300-ER

Product Origin:China

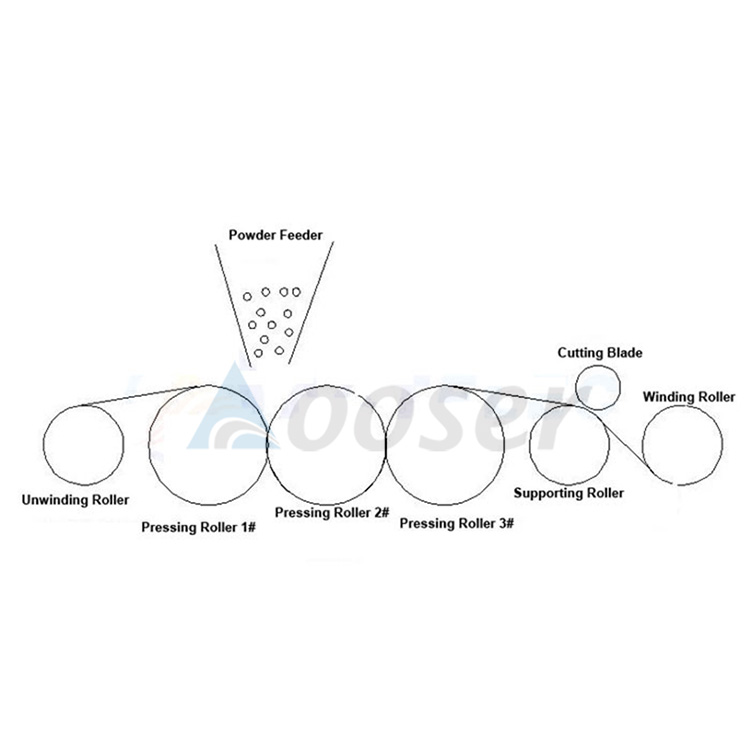

Product Description: AS-MSK-H2300-ER high temperature hot rolling roll press, 15 tons pressure 200℃ constant temperature rolling, 300mm roll width ±0.005mm thickness control, HRC60 high hardness rolls, suitable for continuous production of battery electrode and composite foil, PLC touch control integrated hydraulic pressure stabilization system.

Product Description

AS-MSK-H2300-ER is a roll-to-roll hot rolling press with max. the working temperature of 200°C and Max. the pressure of 15T. The 300mm wide rollers (HRC60) allow the process of various materials such as battery electrodes, plastic media, soft metal, and composite foils. The built-in hydraulic pressure regulating system provides stable pressure control over the entire calendaring process. It is an ideal tool to increase material density and achieve better surface quality.

|

Features |

- Featured patented electrical driven heat - able rollers with accurate and uniform temperature control. Upto 200 °C working temperature. |

|

Voltage |

- Three Phase 220VAC +/- 10%, 50/60Hz |

|

Power Consumption |

- 8.5KW |

|

Roller Driving Motor |

- 1KW inverter duty AC motor |

|

Roller Diameter |

- 200 mm |

|

Roller Width |

- Max. 300 mm |

|

Surface Hardness of Rollers |

- HRC 60 - 62 (<5% hardness attenuation when heat up to 200°C) |

Company Profile

Xiamen AS battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AS Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Certificate

Cooperative Partner

Contact: Jason Wang

Phone: 13580725992

E-mail: sales@aooser.com

Whatsapp:13580725992

Add: No.429 Guangming Road, Shenzhen City, Guangdong Province

We chat